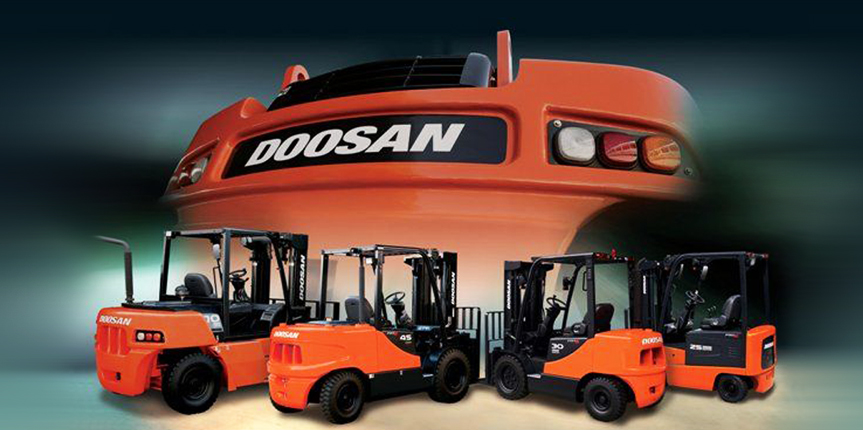

Doosan: Innovation, Convenience & Comfort

KMH is a proud dealer of all Doosan equipment – Doosan offers top class equipment based on environmentally-friendly products with low gas emission and noise and vibration.

With over 120 years of business experience, Doosan is driving innovation in 38 countries. Doosan is made up of two Korean words. ‘Doo’ means a unit of grain, while ‘San’ means a mountain. Together, they mean ‘little grains that can build a mighty mountain’, suggesting that great things can be achieved when even the tiniest forces join together in a unified effort. The name represents the mission to harness the efforts of every individual to keep progressing until we reach our goal.

Doosan produces over 100 models of forklifts including engine and electric forklift trucks, reach trucks and warehouse equipment, covering most of material handling equipment range. All of our products are focused on reliability, operator convenience and comfort as well as powerful performance, enhancing performance and profitability.

Doosan Sit-down Electric Trucks

Doosan Sit-down Electric Forklifts are Compact forklifts that provide the best combination of performance, efficiency, and value on the market. Doosan’s AC Drive and Hydraulic technology on this family of trucks enhances your investment in equipment, personnel, and efficiency.

Doosan Walkie Pallet Trucks

Doosan Walkie Pallet Trucks are highly efficient and reliable forklifts with productivity enhanced features. Doosan’s BW-7 Series is packaged to take on loads from 3,300 lbs. to 6,500 lbs. and come equipped with some of the greatest standard features available in the forklift industry to date.

Doosan IC Cushion Forklifts

Doosan Cushion Tire Lift Trucks offer the ultimate combination of power and performance, reliability, operator comfort, and economy. This series of trucks provides a well balanced mix of enhanced technology, operator comfort refinements, performance efficiencies and serviceability advances which will help to increase productivity and lower your operating costs.

Doosan Pneumatic Forklifts

Doosan Pneumatic Lift Trucks are robust and durable forklifts to handle the toughest tasks in the most demanding of applications with speed, power, and efficiency. These trucks offer the ultimate combination of power and performance, reliability, operator comfort, and economy.

Doosan Hand Pallet Trucks

Meet Doosan’s NEW HPT28, our durable 5,500 lb capacity unit developed to meet your warehousing needs. Highly efficient and reliable forklifts with productivity enhanced features.

If you’re interested in additional information on any of the Doosan Forklift Series and or would like to request a quote, please use the form below to submit your request or contact your local KMH Representative at 888-564-7978.